First National Technical Center with latest state of the art patented equipment in cooperation with Cambridge Dynamics and Beckhoff New Automation Technology (PLC systems).

*Covering

a total area of 5,000 sq.m (or

50,000 sq.ft)

- This implemented technical center consists of Dynamic & Static testing

managed by a R&D team of 30 engineers.

*Total

investment > RMB 50 million.

*Core

strategic project.

*Fully

state-of-the-art patented design and equipment - Operated by the industry

experienced specialists.

*The

test center is fully insulated with air exchanges (environmentally friendly)

and consistent humidity and temperature (to provide best testing

conditions).

*The

test will be running on ASAE, DIN, ISO, RMA & SAE standard.

Testing Centre will have the following Rigs:

* 10-off 15kW Rigs

* 10-off 30kW Rigs

* 10-off 75kW Rigs

* 2-off 100kW Rigs

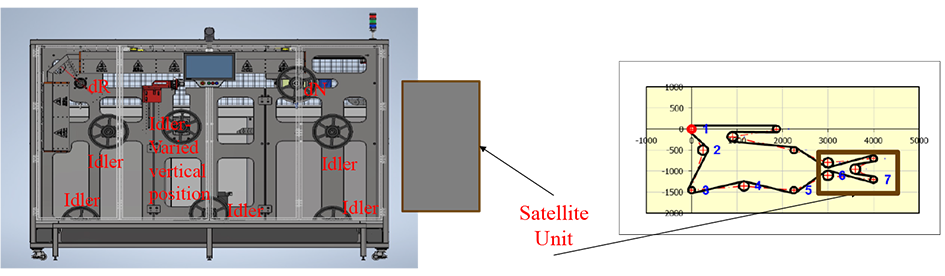

30kW Rig containing:

*DriveR Pulley.

*DriveN Pulley.

*6 off Idler Pulleys.

*A satellite unit can increase belt length capabilities, adding 5 more idler pulleys

Department will have a fully inclusive IT system in control of:

*Test assignment.

*Product input.

*Pulley lifetime monitoring.

*Calibration.

*Real time data and photograph collection.

*Automated reporting (incl. identical testing of different manufacturers across multiple rigs).

*Authorized access is possible globally – Real time

Rig advanced features are as follows:

*Ability to fit a large range of belt lengths (800mm to 16000mm) and types (Wrapped V-Belt, Cogged V-Belt, Ribbed Belt, Variable Speed Belt, Banded Belt, as well as Timing Belt).

*Belt life is greatly affected by temperature - our rig will capture life time behavior of:

- Working temperature changes due to friction.

- Belt life and performance under incremental temperature change.

- Slip on Driver pulley versus Driven pulley as slippage causes heat variations in the belt.

*Our rig will test and capture the physical changes of the belt under the following conditions:

- Effect of back bending on belt due to bending around back idlers.

- Wear of belt through dynamic micro photography.

- Dynamic tension loss.

- Real time belt measurement via infrared lasers.

- Early failure detection, vibration sensor paired with temperature change - facilitating better diagnosis of belt failure.

*Comparative testing (versus competition or others) through multiple rigs output from live reporting canl be linked on real time.

Data capture:

All data are saved for analysis using our integrated AI - Able to investigate and determine the root cause of failures and determine which of the belt elements will need improvements, updates, and/or changes. Able to further develop new generation programs based on our AI further data analysis and formulations.

Testing Centre will have the following Rigs:

* 10-off 15kW Rigs

* 10-off 30kW Rigs

* 10-off 75kW Rigs

* 2-off 100kW Rigs

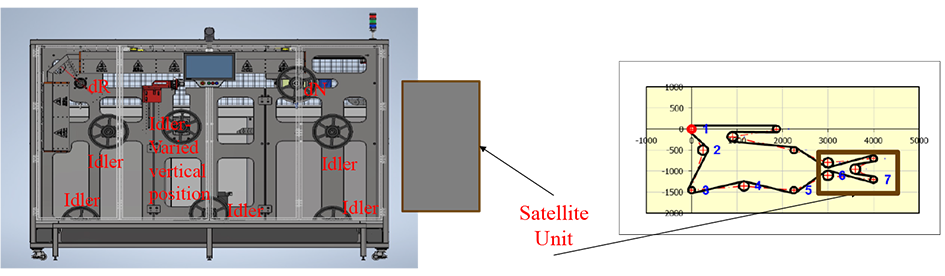

30kW Rig containing:

*DriveR Pulley.

*DriveN Pulley.

*6 off Idler Pulleys.

*A satellite unit can increase belt length capabilities, adding 5 more idler pulleys

Department will have a fully inclusive IT system in control of:

*Test assignment.

*Product input.

*Pulley lifetime monitoring.

*Calibration.

*Real time data and photograph collection.

*Automated reporting (incl. identical testing of different manufacturers across multiple rigs).

*Authorized access is possible globally – Real time

Rig advanced features are as follows:

*Ability to fit a large range of belt lengths (800mm to 16000mm) and types (Wrapped V-Belt, Cogged V-Belt, Ribbed Belt, Variable Speed Belt, Banded Belt, as well as Timing Belt).

*Belt life is greatly affected by temperature - our rig will capture life time behavior of:

- Working temperature changes due to friction.

- Belt life and performance under incremental temperature change.

- Slip on Driver pulley versus Driven pulley as slippage causes heat variations in the belt.

*Our rig will test and capture the physical changes of the belt under the following conditions:

- Effect of back bending on belt due to bending around back idlers.

- Wear of belt through dynamic micro photography.

- Dynamic tension loss.

- Real time belt measurement via infrared lasers.

- Early failure detection, vibration sensor paired with temperature change - facilitating better diagnosis of belt failure.

*Comparative testing (versus competition or others) through multiple rigs output from live reporting canl be linked on real time.

Data capture:

All data are saved for analysis using our integrated AI - Able to investigate and determine the root cause of failures and determine which of the belt elements will need improvements, updates, and/or changes. Able to further develop new generation programs based on our AI further data analysis and formulations.